Thank you for the opportunity to show you just some of the many services we provide to help you or your business now or in the future.

Just scroll down to a service that you require and more detailed information will be given.

We provide so many services that we have just listed a few, please feel free to just contact us and we may be able to help further, or we are more than happy to arrange an appointment to visit and discuss requirements or services that you may require.

Appliance Testing & Tagging

Testing and tagging of all electrical appliances and equipment to ensure your workplace areas are compliant under the occupational health and safety standard as3760 2003.

What we test are all appliances that use a plug or lead to connect to the power supply or any appliance that may be a danger in the event of a fault. The way we test is in accordance with Australian standards, every appliance that

passes its test is tagged with a unique number to help in asset control and future testing of the appliance. A report is printed out to leave onsite ready for inspection by a WHS representative of the workplace or work cover if required.

We can also supply an overall report of all tests done if required in pdf if required free of charge

Failed appliances also can be assessed for repair and repaired if requested or danger tagged if found not to pass the tests and

standards to prevent the further potential risk of a failed item is used.

Data Communications

Emergency Lighting

INSPECTION, TESTING AND MAINTENANCE OF EMERGENCY AND EXIT LIGHTING

When the power goes off in a building, people look to the Emergency Lighting to guide them to safety. In a fire, Emergency Lighting is especially critical. It helps prevent panic, minimizes injuries and protects lives. Unfortunately, Emergency Lights don’t always get the inspection and maintenance necessary to ensure that they will work when you need them most.

AUSTRALIAN STANDARDS AS2293.2 REQUIRE THAT ALL EMERGENCY AND EXIT LIGHTING BE INSPECTED AND TESTED EVERY 6 MONTHS.

These standards set the requirement for full Inspection and test procedure of the systems, and that will work for a period of not less than the required in-service duration when the main electrical system fails. The Standard also lays out the recording of actual tests and of the problems found and rectification action must be signed off once undertaken.

The safety of the occupants of the building depends upon the building manager having the maintenance carried out conscientiously and as required by the Australian Standards.

Solect Electrical provides such an Inspection service and maintenance. We will carry out appropriate Inspection and maintenance procedures and log records of tests and repairs into a logbook manual. This manual details Site Layouts and Six Monthly and Yearly Tests, with reports on any defective works or repairs on tests, carried out. We will organise tests and repairs to be carried out in a professional manner with minimal disruptions to workplace activities and at times best suited for your company or business.

Power and Lighting

- Office powerpoints

- Power rail stations

- Factory power

- Warehouse power

- 3-phase power for forklift machinery etc

- Office lighting

- Boardroom lighting

- LED office lighting

- Upgrades to LED lighting for offices, warehouses and factories to save money with reduced energy consumption

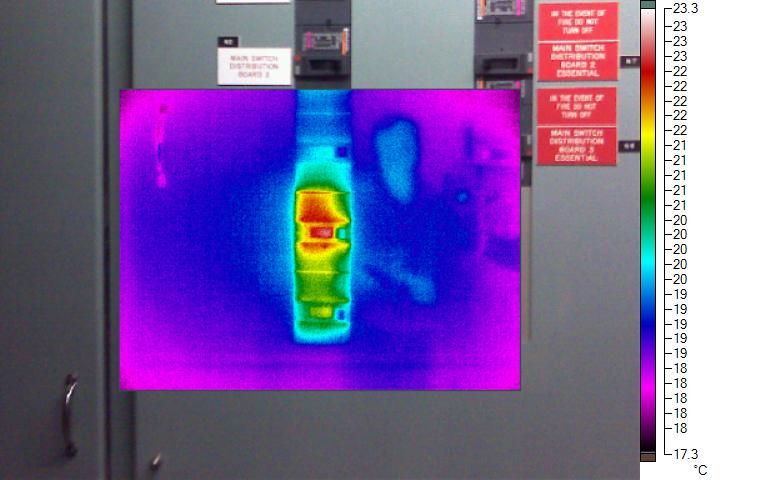

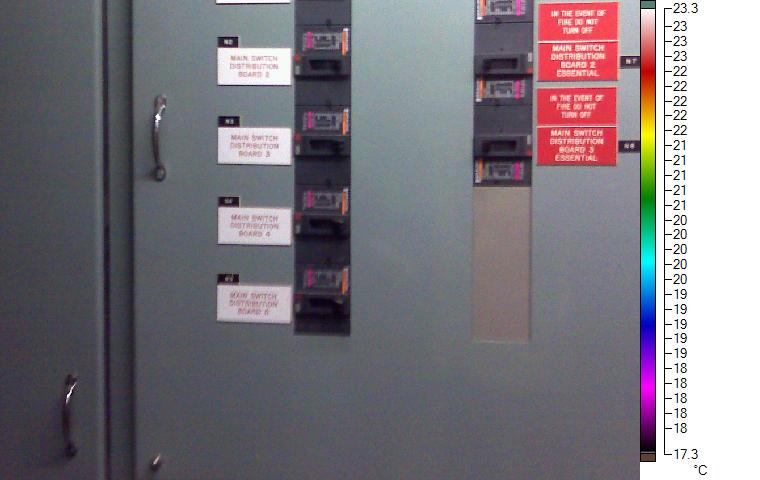

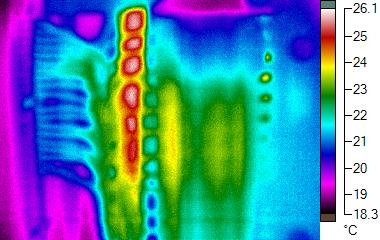

Thermal Imaging

How Solect Electrical Thermal Imaging Can Help You & Your Business “Prevention is better than cure” is a timeless adage that we are all familiar with. It can be applied to all situations and in any environment. In business, most successful enterprises incorporate this philosophy as part of their

commercial success.

Solect Electrical understands the importance of businesses operating without the risk of breakdowns or interruptions caused by electrical faults or problems.

The Solect Electrical preventative maintenance system offers Thermal Imaging (Electrical Infra-Red Hot Spot Detection) based on the most modern date digital technology for all levels of industry from complex modern industrial plants to multilevel

office accommodation at a competitive realistic price.

Using the above process Solect Electrical can carry out an infrared thermographic survey of all electrical/mechanical distribution switchboards and other reticulation equipment

providing detailed photographic results for analytical purposes. Data is collected at load conditions of the day without the interruption of a costly shutdown to power and collated into

a concise detailed report.

The detailed reports generally show how and why the faults have occurred, recommendations of repair and priority ratings for engineering analysis. It is important to note that these reports can be tailor-made to suit your specific requirements from single graphic presentations to detailed, complex, accurate engineering data.

Our reports can be utilised for:

- Preventative electrical/mechanical maintenance

- Insurance Assessing

- Quality Assurance

- Auditing maintenance programs